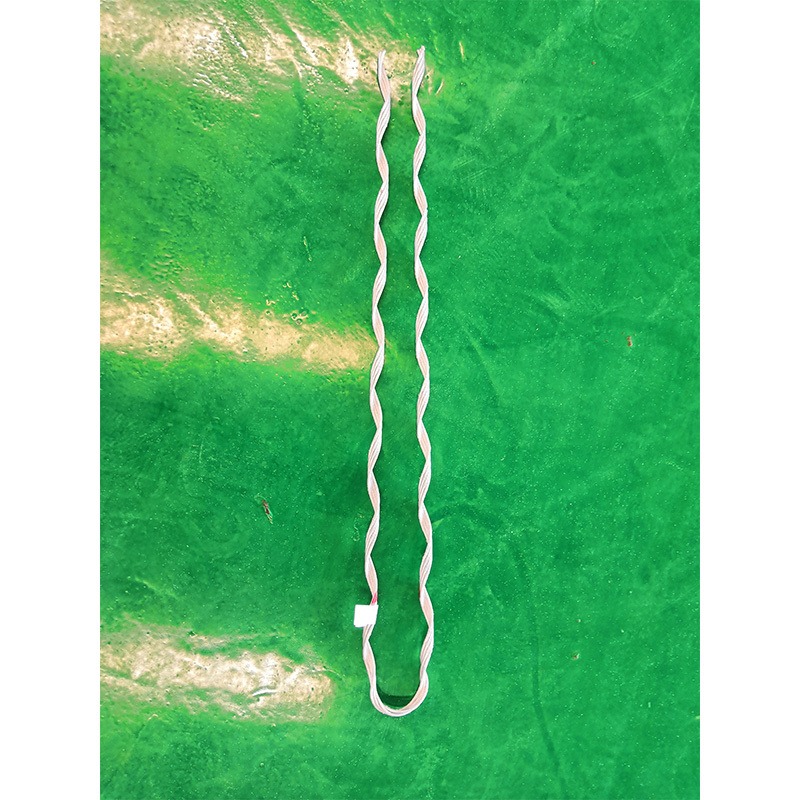

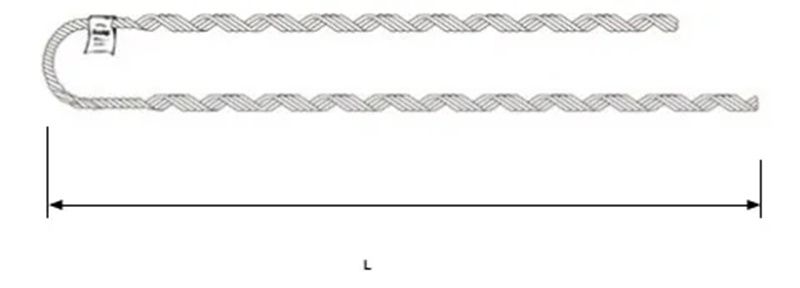

Helical Dead-end Clamp

Helical dead end is a reliable and durable solution for securing overhead conductors in transmission and distribution line construction.

Helical Dead End for Conductor

A helical dead end is a specialized hardware device used in the construction of overhead transmission and distribution lines. It is designed to secure the end of an overhead conductor to a supporting structure such as a pole or tower. Constructed from high-strength steel rod twisted into a helical shape, it provides reliable anchoring for conductors.

Features

High-strength construction for robust performance

Corrosion resistance to withstand harsh environments

Ability to endure extreme weather conditions

Helical shape enhances strength and stability, reducing the risk of conductor breakage or sagging under heavy loads

Advantages

Ease of installation: Can be quickly attached to conductors using standard hand tools, no need for specialized equipment or skilled labor

Versatility: Compatible with various conductor types and sizes, suitable for a range of construction projects

Cost-effectiveness: Relatively inexpensive compared to other conductor hardware, ideal for budget-constrained projects

Application

Application

Helical Dead-ends for conductor are used to bear full tension on bare conductors or overhead insulating conductors in transmission and distribution lines. They connect conductors to towers (or poles) via matching fittings such as clevis thimbles and socket eyes, serving as ideal substitutes for traditional clamps like bolt-type tension clamps, compression-type tension clamps, and wedge-shaped tension clamps.

Material

Galvanized steel, Aluminum alloy, or Copper alloy

Characteristics

High gripping strength for conductors, supporting high tensile force:

For transmission lines: Provides gripping strength of no less than 95% of the conductor's CUTS (Calculated Ultimate Strength)

For distribution lines: Offers gripping strength of no less than 65% of the conductor's CUTS

Reliable performance in extremely adverse environmental conditions, maintaining sufficient gripping strength throughout its service life. Material compatibility with conductors prevents electro corrosion, protecting both the product and the conductor.

Even stress distribution without concentration on the conductor, ensuring excellent protection for the conductor.

Tool-free installation: Can be installed manually without special tools, simplifying the process for users.