Preformed Armor Rods

Armor rods are designed to protect cables from bending, compression, abrasion and flashover. They are also used to repair damaged aluminum-based conductors and restore the mechanical strength and electrical conductivity of the conductors.

Preformed Armor Rods

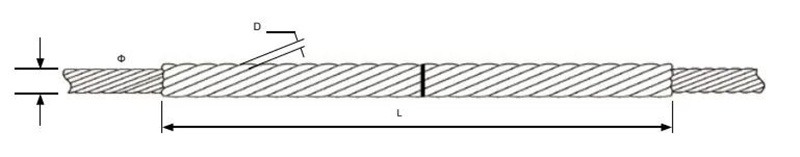

Preformed armor rods are specialized components designed to protect cables from bending, compression, abrasion, and flashover. They also serve a critical role in repairing damaged aluminum-based conductors, restoring both their mechanical strength and electrical conductivity. As essential accessories for power and communication infrastructure, they play a key role in ensuring the reliability of transmission and distribution lines.

Applications

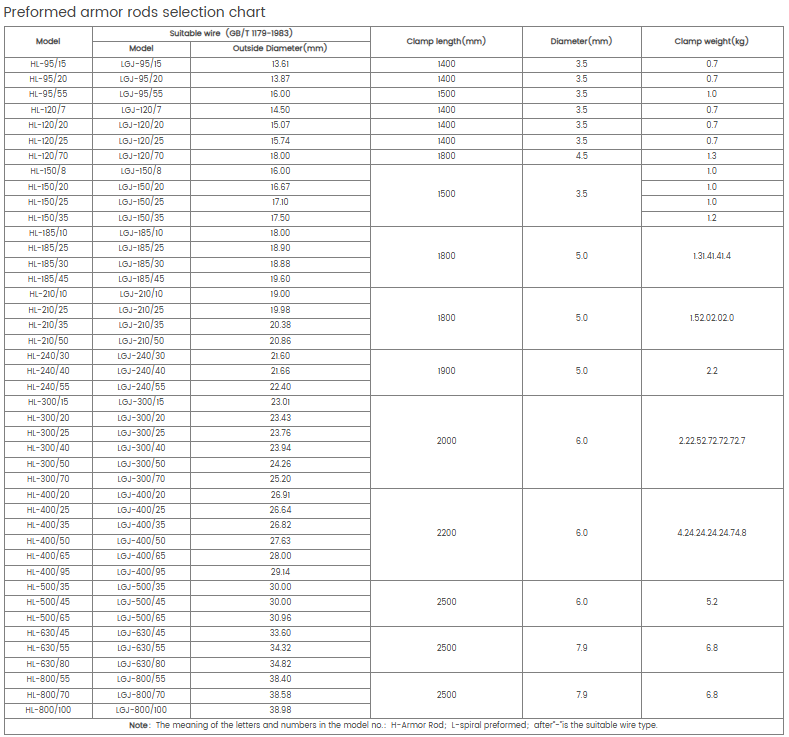

Armor rods are suitable for use with a range of conductors, including:

Aluminum conductors

Steel-reinforced aluminum conductors (ACSR)

All-aluminum alloy conductors (AAAC)

Aluminum-clad steel conductors

Specifically, Boersen Photoelectric armor rods are widely applied in transmission and distribution lines. For phase conductors, they are typically made of aluminum alloy, while aluminum-clad steel is used for overhead ground wires, ensuring compatibility with conductor materials.

Material & Identification

The material of armor rods is carefully matched to the conductor’s surface material to prevent corrosion caused by galvanic or electrolytic reactions between dissimilar elements. All types of armor rods feature a color code, which simplifies conductor size identification and serves as a reference mark during installation.

Features

Versatile Lengths: Available in both single support and double support lengths to suit diverse application needs.

High Thermal Resistance: Rated for continuous use in high-temperature environments, including 250°C for suspension clamps and ACSS repairs, and 125°C for ACSR repairs.

EHV Compatibility: Equipped with PARROT-BILL ends to meet corona onset and Radio Influence Voltage (RIV) requirements for most Extra High Voltage (EHV) applications.

Easy Installation: Can be installed manually without the need for special tools, streamlining on-site operations.

Customizable Length: Lengths can be determined based on customer specifications, ensuring a tailored fit for specific conductors.

Manufacturing

Preformed armor rods are factory-made with precise pre-formed shapes, ensuring a tight grip on conductors and ground wires when installed. They are crafted from materials compatible with the target conductor, with raw materials including:

Aluminum wire

Galvanized steel wire

Aluminum-clad steel wire

Customers select the appropriate armor rod material based on the conductor’s raw material, ensuring optimal performance and longevity.